Happy 2018 everyone! Now that we’re getting back into the swing of things after winter break, it’s time to share some SEAL updates. We have lots more this month ![]()

Alverno has posted their first update! They are divided into four groups this year: CO2 Reduction, Classic SEAL, Acid SEAL and Deconstructed Oxide Laboratory Printer Happily Inking Nonfoods (DOLPHIN) SEAL.The goal of the CO2 Reduction group is to utilize the SEAL kit in a setup that allows them to perform CO2 reduction by bubbling CO2 from subliming dry ice into the electrolyte. They will be looking at titanium dioxide, zinc, nickel for their efficacy at photoactive reduction of CO2.

The Classic group created some protocols such as using the kiln or spotting plates that will be uploaded to protocols.io soon. Last year, Alverno struggled with consistency but this year have had much more success replicating results for Fe and Ni plates. Next up is testing Manganese and Calcium salts as found in Photosystem II. The plates made in Classic SEAL can then be used by other groups, such as comparing the results in sodium hydroxide solution with the results Acid SEAL might get in hydrochloric acid.

The DOLPHIN group is designing a printer this year that can print out spots rather than pipetting them— this could help with making sure the spots are aligned with the template and are consistent. There’s some programming involved and it’s unclear which metal solutions will be compatible with the printer, but they are excited to see what happens!

Beckman’s Group 1 made ratios of 1:1, 1:2, 1:3 and 1:4 of 0.03M Cr(NO3)3, 0.03M Cd(NO3)2. They UV treated plate BHS-1-50 for five minutes and then spotted the plate with different ratios, including 0.03M Fe(NO3)3 standard spot in the top right corner.

Group 2 tested a plate they made previously which included a chromium nitrate, aluminum nitrate, and cadmium nitrate solution. They also spotted a chromium nitrate FTO plate and plan to test it next week.

Group 3 spotted BHS-1-60 with ratios of 2:1, 1:2, and 1:1 of 0.03M Fe(NO3)3 and 0.03M Al(NO3)3, with the iron standard in the top right corner. Iron nitrate is a significant and well-known photoanode while aluminum nitrate may further enhance the effective OER (oxygen evolution reaction) properties. Therefore, the main goal for the next session is to research and test another effective OER catalyst according to the results obtained with this plate.

Group 4 is testing the effects of varying lengths of UV treatments on the FTO plate. They first exposed an FTO plate to the UV treatment in the germicidal cabinet for thirty minutes and spotted with Fe(NO3)3, let it dry, then baked in the kiln. They repeated this process with a new plate for 15 min, 10 min and 5 min. They will compare the results of these plates to see if longer UV exposure time makes a difference.

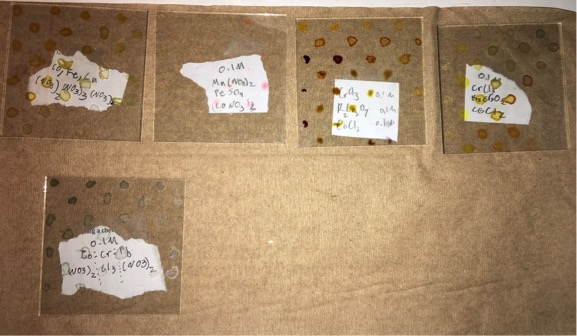

Canyon Crest‘s first update as well. They had some issues with solutions evaporating over break, but were able to remake them and spot 5(!) plates shown below:

This meeting we were also able to use some odder solutions including using potassium dichromate (K2Cr2O7) which they had to stabilize with Nitric Acid. Mixing this with a 0.1M solution of CrCl3 we created a 0.1M chromium dichromate solution, Cr2(CrO7)3 (aq). They were surprised at its solubility, and will keep it for next meeting. They also speculated about isolating titanium in solution – converting between the titanium dioxide available in the stockroom and usable titanium tetrachloride by using nitric acid. However, they need to find a way to add chloride ions to the equation…

Also here is a link they found to a recently published Columbia University study on a new technology for seawater electrolysis which yields Hydrogen fuel as a product!

San Marino‘s Blank Team focused on the copper nitrate “incident.” They explain “We know something is wrong because nearly every spot on the plate began the test with a “bar” (see pictures of test runs) of the same level (green or blue-green). We also know that the problem has something to do with the machine/kit. The spots that were “outliers” (not having the same level as all the others) were made from a solution of only a copper salt.” Thoughts for them?

Green Team re-spotted their 10-31 plate, with Fe3+, Fe2+, Cu2+, Co2+. First scan produced nothing of significance. It was mostly dark blue. The lone outstanding spot was 50:50 Fe3+ and Zn2+. Spots began to crack and flake in the plate. The dark current was around 0.3V. (Sound familiar MSS KEY team? You should compare notes!)

Mayfield‘s Team KEY made plates to test additional metals with the successful FeZn material. 9:1:1 FeZnMg; FeZnNi; FeZnCu; FeZnAl; FeZnCo. Team JES had to remake their plates 3, 4 & 5 which to refresh your memory are a series of plates with Fe(NO3)3 and Ni(NO3)2 layered with various applications of a tesla coil. Plate 3 is Fe & Ni layered with 3 min of Tesla coil between the layers, plate 4 is treated with Tesla coil before the Fe, and plate 5 is treated with the tesla coil after both layers. After testing this series they hope to move on to experimenting with absorption spectra and artificial photosynthesis.

Recent Comments